Time for a wee update though not a lot of progress that can been seen really. As I started working on the wiring and metering out wires etc. I realised that i needed to really get the heater ducting and lower vents finished in order to see what space I had where for cables and other things. To do this I needed to get the under trays fitted.

The under trays need set into place then held at the front with clamps whilst the back is marked then drilled through and on up into the steering column support bar in a few places, then tapped. The right and left trays need this done, the center one has holes in the 2 supports already and just the tray needs drilled.

The fronts of the trays that fit either side will get held in place with the dash lip as it has to be bolted underneath.

With the rear mounting holes done, The 76mm hole was cut with the holesaw for the adjustable heater duct and also a 12v power socket was added as well, This was done for both the passenger and the drivers side.

On the passenger side I also added a bank of relays as I needed extra on the car that wasnt covered by the GD loom. I need 1 for the fuel pump, 1 for firing the 2nd cooling fan as I'm using 2 stage cooling from the GM ECU, 2 more relays are required for the heaters in the drivers and passenger seats. I also need one more for part of the alarm system. The last one at the moment is spare, it will either stay a spare or its always there just encase or an emergency if required to swop with another.

Not loads of room with all the heater hoses on the passenger side along with the wiper motor.

Above pic shows the T piece which splits the air to the demist on the dash and also the lower hot ait vent. next hmmmmmm more wiring in the dash area :)

Welcome to the build of my Gardner Douglas 427. Hopefully the build will go better than my blog attempt, this will take some tweaking :)

Wednesday, 9 November 2011

Sunday, 6 November 2011

Wiper motor and cockpit wiring

Time to get the wiper motor and drive mech into place, first the motor was bolted onto the bracket and the drive and tube curved across the dash past the 2 wiper spindle mechs.

Once everying was in place correctly I marked the bundy tube where the cuts had to be made and also running it about 100mm past the 2nd wiper spindle. Removed the whole lot again and cut the tube pieces and flared all the ends with my flaring tool. All put back and bolted into place. Will have to check operation at some point once the electrics are sorted to make sure its parking in the right place and not 180deg out.

With the wiper motor in place I bolted in the dash air vents then set about looking at piping the dash vents and the vents that blow the air down towards the footwells, The pipes need to be split and I had seen before where people made up T pieces etc. I got a handlier way around this and its a perfect fit for the flexi tubing :) I used 2 waste T pieces and cut of the ends where the rubber O rings are housed the remaining pipe is the excact diameter required. No particular reason I painted them balck the same colour as the pipe. I 'll get back to finishing this job at a later date.

Also got stuck into the wiring behind the dash, I ran near ll the cables that i could behind the dash and inside the car so quite a bit of work in this area, will take me a while and my head is pickled for today :).

Once everying was in place correctly I marked the bundy tube where the cuts had to be made and also running it about 100mm past the 2nd wiper spindle. Removed the whole lot again and cut the tube pieces and flared all the ends with my flaring tool. All put back and bolted into place. Will have to check operation at some point once the electrics are sorted to make sure its parking in the right place and not 180deg out.

With the wiper motor in place I bolted in the dash air vents then set about looking at piping the dash vents and the vents that blow the air down towards the footwells, The pipes need to be split and I had seen before where people made up T pieces etc. I got a handlier way around this and its a perfect fit for the flexi tubing :) I used 2 waste T pieces and cut of the ends where the rubber O rings are housed the remaining pipe is the excact diameter required. No particular reason I painted them balck the same colour as the pipe. I 'll get back to finishing this job at a later date.

Also got stuck into the wiring behind the dash, I ran near ll the cables that i could behind the dash and inside the car so quite a bit of work in this area, will take me a while and my head is pickled for today :).

Friday, 4 November 2011

Exhaust clamps / cable cover etc

I had noticed the clamps that come with the exhaust were not stainless steel even though the exhaust was and also they dropped well below the exhaust. I decided to remove them and add Mikalor stainless steel clamps.

Looks at lot better with these clamps and they wont cause any ground clearance issues :)

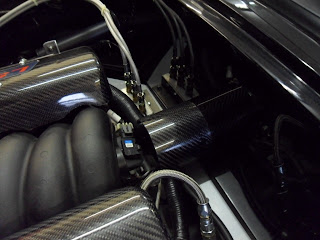

On my mind for a while was how to tidy/conceal all the cables for the ECU, main power and everything else that I had routed through the middle of the bulkhead. I done this in order to try and keep every thing else clutter free around the engine bay. The end result is my new cover :)

Looks at lot better with these clamps and they wont cause any ground clearance issues :)

I got some foam strip as well that was sticky on one side I used this to seal around the covers for the wheel arch compartments to stop any moisture getting in.

Thats all for now, Next job on my list is the wiper motor assembly and drive links along with some pipe work for the pedal box.

Wednesday, 2 November 2011

Engine bay

The flexible hose from the fuel rail to the copper fuel line running down the chassis needed routed a bit better and some heat shrink on it to stop it rubbing on the electrical cables. in order to do this the Rocker cover bracket needed cut and re welded to stop the eblow fouling.

With that job done the covers could be fitted :) The connections from the heater box to the stainless heater pipes all linked up now as well.

The radiator mount was bolted in then the air filter was fitted and also the radiator, took a while to get done and everything connected up. The carbon link pipe was also dilled and the air temp sensor fitted.

All in all pretty happy with the progress this past month, project seems to be coming along heaps and bounds :)

With that job done the covers could be fitted :) The connections from the heater box to the stainless heater pipes all linked up now as well.

The radiator mount was bolted in then the air filter was fitted and also the radiator, took a while to get done and everything connected up. The carbon link pipe was also dilled and the air temp sensor fitted.

All in all pretty happy with the progress this past month, project seems to be coming along heaps and bounds :)

Tuesday, 1 November 2011

Door trim etc

Decided to get the drivers side door finishers, eschusions etc sorted, also added the Carbon kick plate. Made a start on the fitting the steering column, first was to get it lined up and cut as slot where the bolt wil pass through.

Subscribe to:

Comments (Atom)